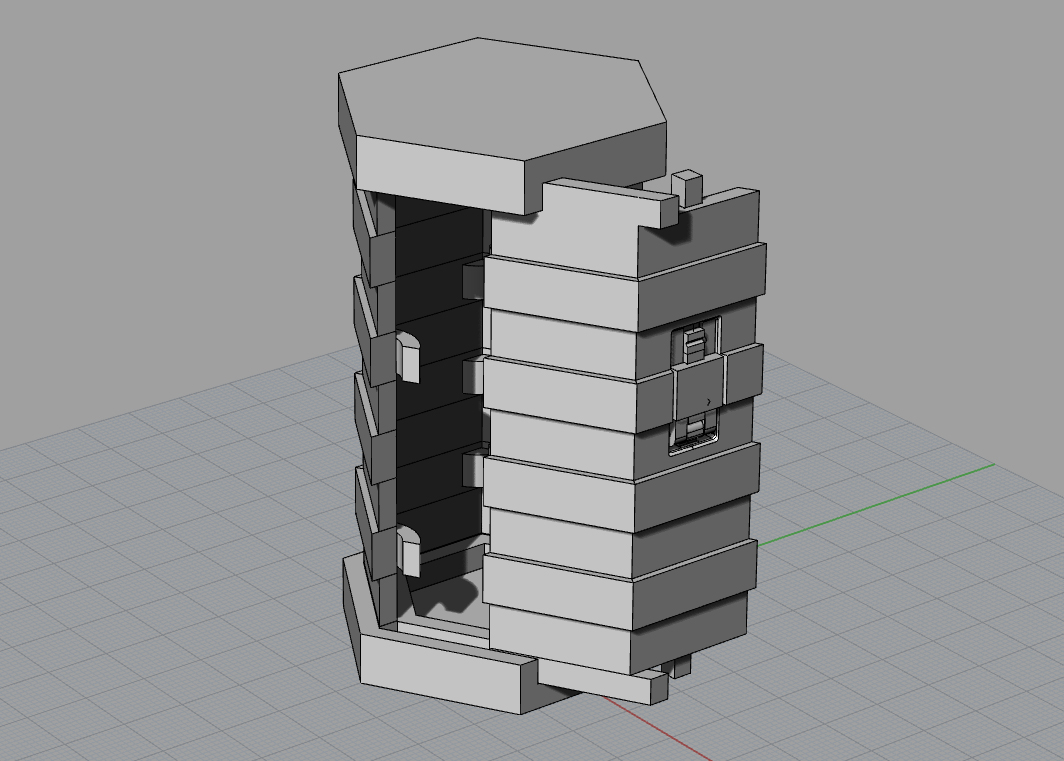

3D Printed EVE Online Container

As part of the "Free Surface Modeling" course at TUDelft, I re-designed an object from a game I used to play called EVE Online, modeled my design in Rhinoceros 3D, and 3D printed it with an Objet Eden260V 3D printer located in the TUDelft Faculty of Industrial Design Engineering.

I set up some criteria to be achieved with the re-designed object.

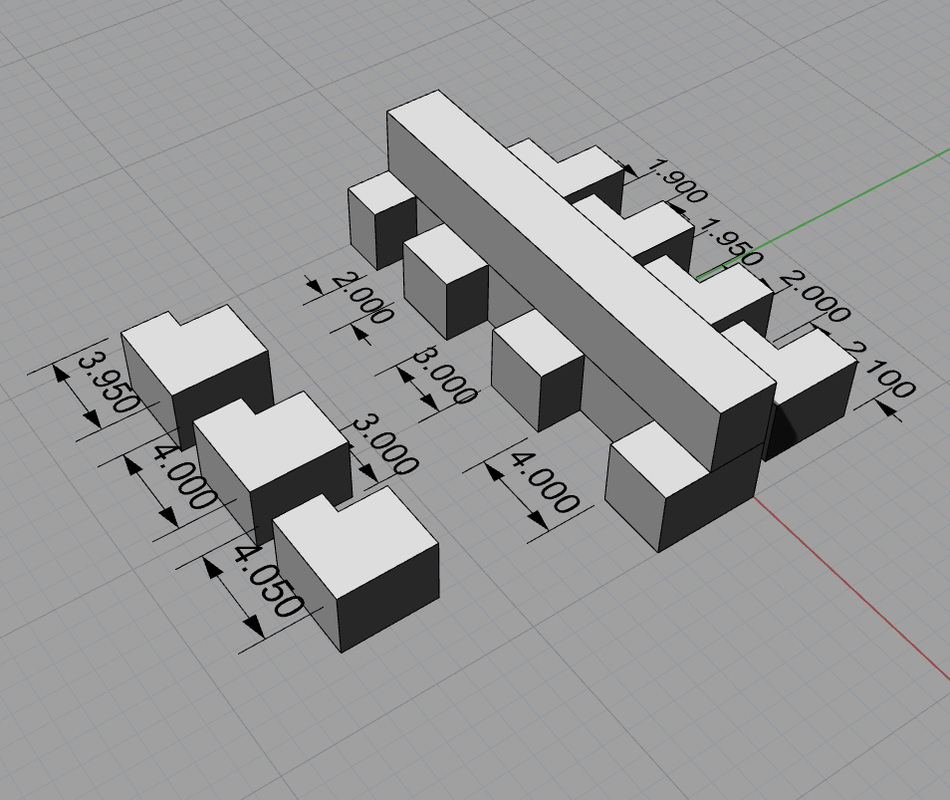

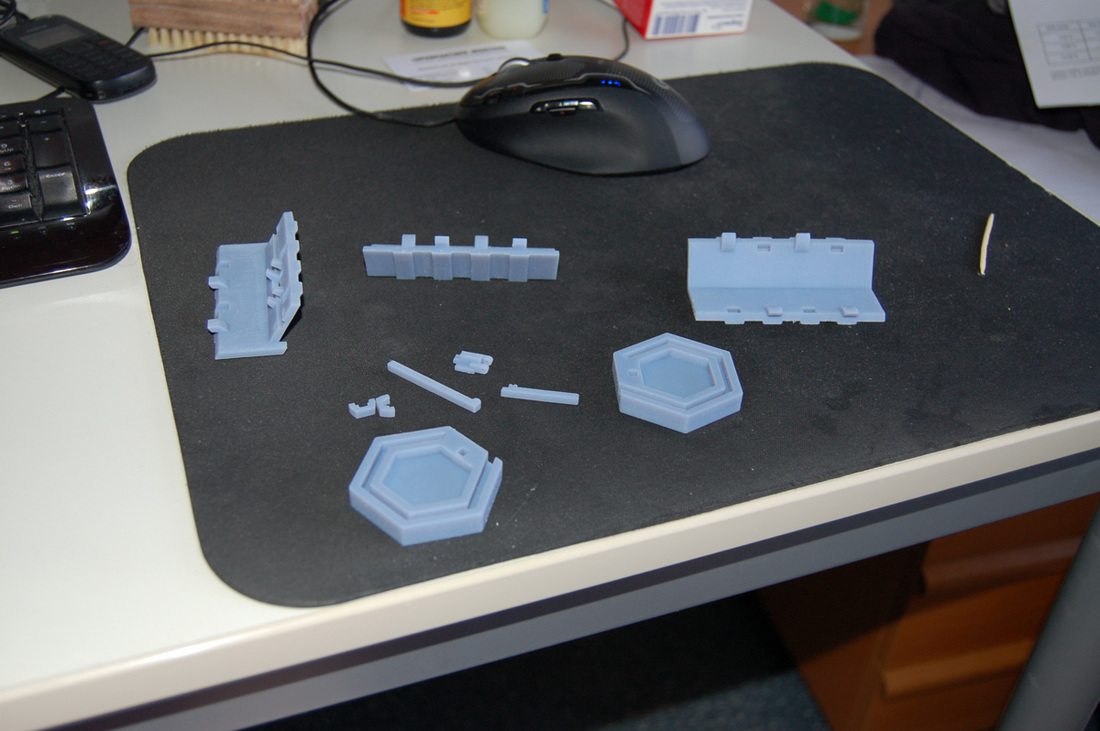

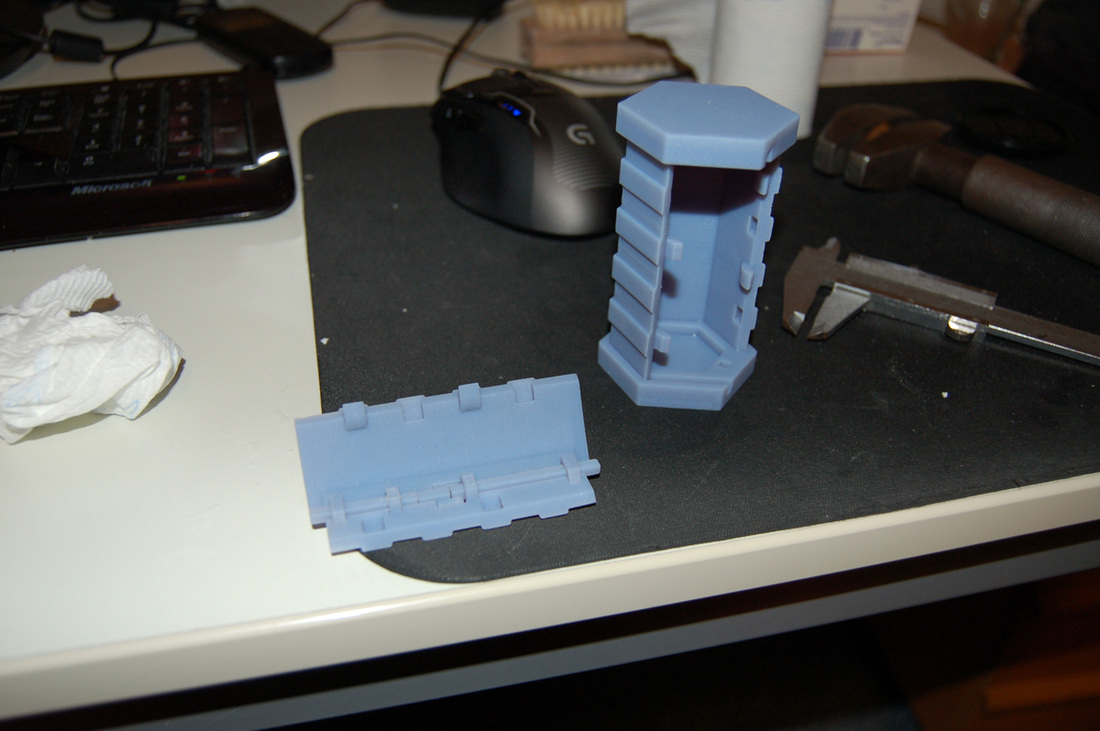

As a first step, I modeled and 3D printed a test part to check the friction fitting tolerances and clearances of the production method.

I set up some criteria to be achieved with the re-designed object.

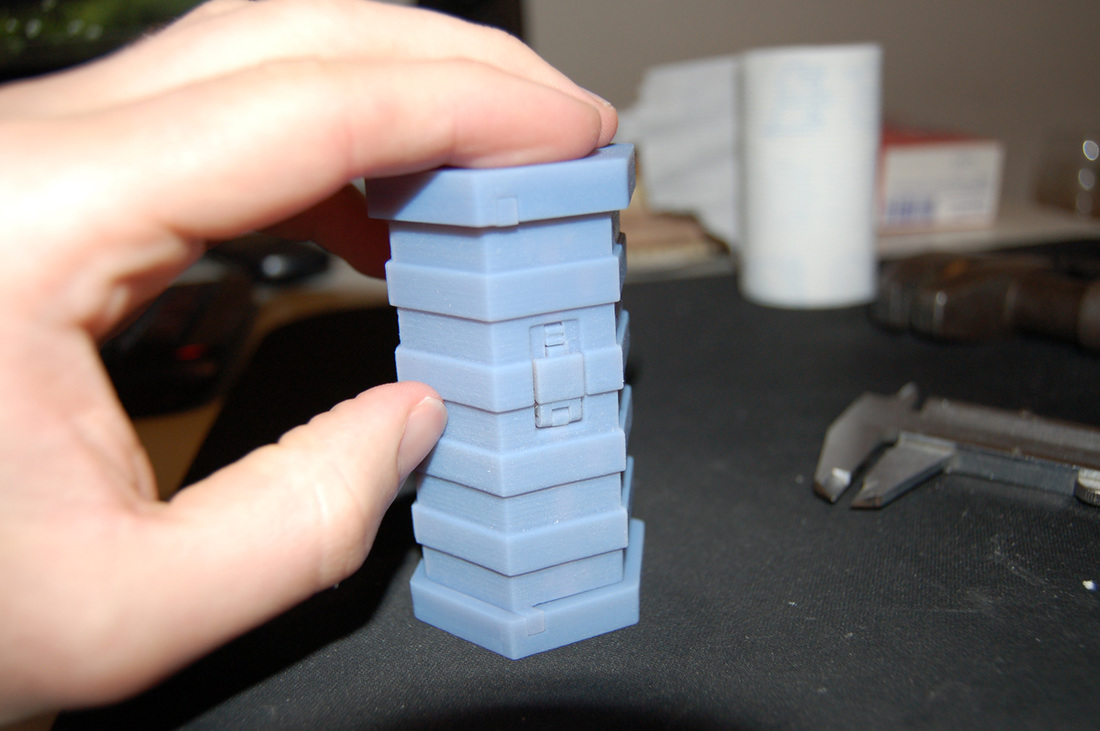

- Once assembled, and locked up, it should resemble the in-game object.

- Modular, and can be disassembled to take less space.

- Friction fitting will be used to assemble the object. (No screw fasteners.)

- It should be structurally sound and can actually stay in one piece once locked up.

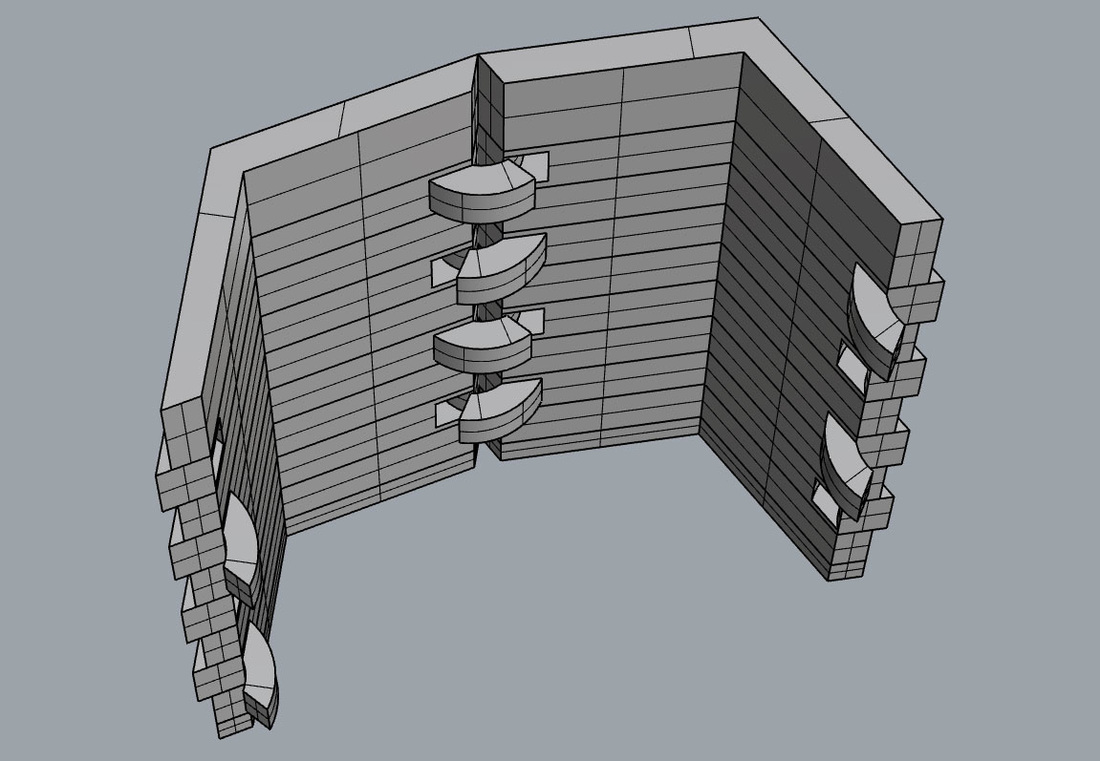

- The door should open in a way the entire interior of the container can be accessed.

- If stacked with other containers, it should be still possible to open the door.

As a first step, I modeled and 3D printed a test part to check the friction fitting tolerances and clearances of the production method.

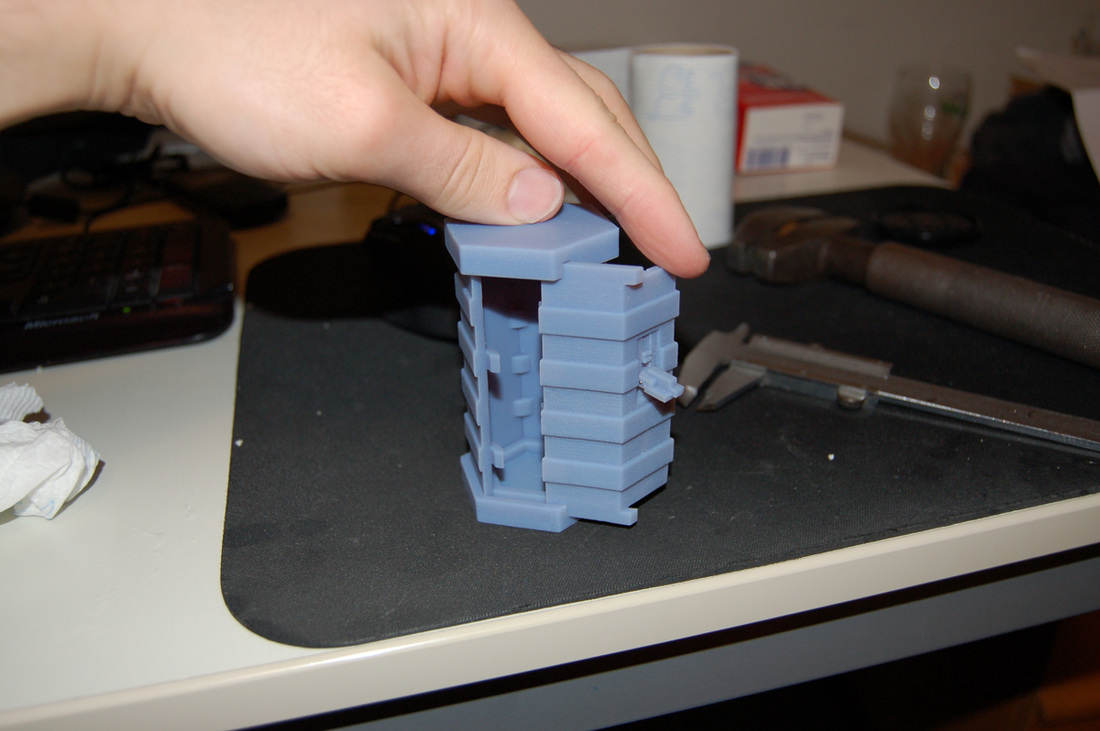

Once I figured out which tolerances to use for friction fits and clearances for the sliding parts, I used a screenshot from the game to create a CAD model, then spent a considerable amount of time to design the door and lock mechanism that would actually work, as the the game artwork is just a surface model of the exterior of the container, without any explanation how anything could actually be put into it.

The CAD model was then sent to the 3D printer, before all the parts were cleaned and assembled.

You can also watch the video of the assembly process.

(I love mechanisms, and parts that are assembled together. I blame the Lego.)

(I love mechanisms, and parts that are assembled together. I blame the Lego.)