Draft Proof Cat Flap

The Netherlands is a windy country, and our cat absolutely insists on going outside regardless of the season. However, the cat flaps on the market seem to have two major problems: Pressure difference can flip them open, and they leak air (often cold air) through them. This means whichever room you install the cat flap to will be colder then the rest of the house, and your gas bill will be higher than what it should be.

This was especially problematic in our case, as the cat flap was installed to the window of my housemate, and anytime the cat entered into the house, it would be followed by a cold gust of air.

There are indeed draft proof pet flaps on the market, but these products are mostly aimed at bigger pets and have high price tags.

For the cat flap, we've set the design criteria as the following:

This also allowed the placement of a towel in between the two flaps, to stop the migration of mud into the house, by soaking up the water off the paws of the cat as it walks over it.

This was especially problematic in our case, as the cat flap was installed to the window of my housemate, and anytime the cat entered into the house, it would be followed by a cold gust of air.

There are indeed draft proof pet flaps on the market, but these products are mostly aimed at bigger pets and have high price tags.

For the cat flap, we've set the design criteria as the following:

- Cheap, ~50 EUR.

- Easy to install, without modifying the house.

- No air leaks.

- Long service life with no maintenance.

- Hardware should not rust (Cat can be in a wet condition).

- Easy to clean.

- Not too difficult to be operated by the cat.

This also allowed the placement of a towel in between the two flaps, to stop the migration of mud into the house, by soaking up the water off the paws of the cat as it walks over it.

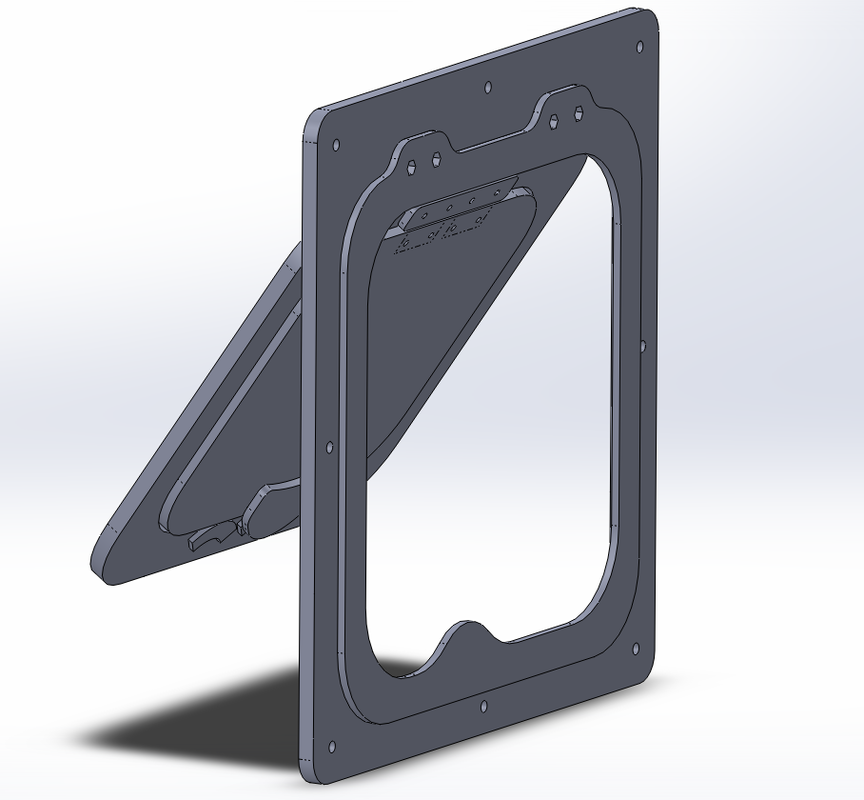

The design is two nested hinged doors that are made air tight with the use of "Y" gaskets. Once closed, a hard drive magnet attracts a metallic plate to make sure the door stays closed and the gaskets are properly compressed. The amount of force applied by the magnets are fine tuned by altering the size of the metal plates.

The parts were produced by laser cutting PMMA sheets at TUDelft. Gaskets, fasteners and hinges were purchased from a hardware store. The PMMA parts were glued together with the appropriate glue, before the rest of the cat flap was assembled with the use of the hinges and fasteners. Gaskets, magnets and the metal plates were adhered into place, before the entire cat flap was screwed into its final spot.

The parts were produced by laser cutting PMMA sheets at TUDelft. Gaskets, fasteners and hinges were purchased from a hardware store. The PMMA parts were glued together with the appropriate glue, before the rest of the cat flap was assembled with the use of the hinges and fasteners. Gaskets, magnets and the metal plates were adhered into place, before the entire cat flap was screwed into its final spot.

Short video that shows the operation principle of the draft proof cap flap.

As of writing this page, the cat flap have seen months of operation with hundreds of uses, without any problems showing up. The criteria was fulfilled successfully, as the room got considerably warmer and the amount of mud coming in through the cat flap was greatly reduced.